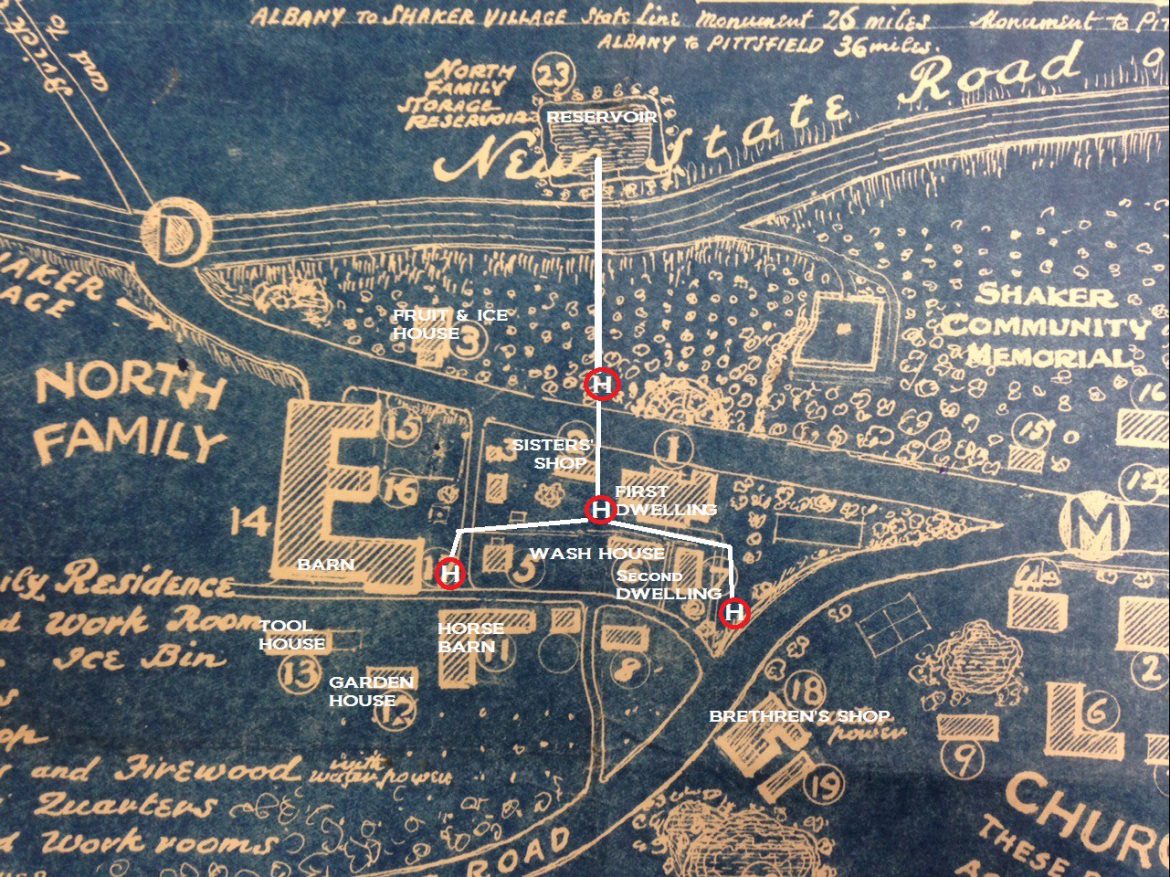

Map of North Family Hydrant Locations and Assumed Piping, North Family, Mount Lebanon, NY, as drawn by A. K. Mosley for the Historic American Buildings Survey, 1939.

A recent blog mentioning the devastating fire of 1875 at the Church Family at Mount Lebanon brought to mind some objects of interest still located at Mount Lebanon’s North Family. In the wake of the fire’s devastation, the North Family made a decision to install four fire hydrants to protect their buildings. In the summer of […]

Ludlow Fire Hydrant, North Family, Mount Lebanon, NY, 1875, Shaker Museum | Mount Lebanon. Staff photograph. This hydrant was position to protect the First and Second Dwellings, the Shakers’ Workshop, and the Wash House. It was the hydrant that supplied power to the Wash House.

A recent blog mentioning the devastating fire of 1875 at the Church Family at Mount Lebanon brought to mind some objects of interest still located at Mount Lebanon’s North Family. In the wake of the fire’s devastation, the North Family made a decision to install four fire hydrants to protect their buildings. In the summer of 1875 they laid five-thousand feet of wooden pipe from a stream running through the East Family downhill to a new reservoir they had dug east and steeply uphill from their dwelling house. The reservoir, two-hundred feet long and fifty feet wide, almost exactly the size of the footprint of their Stone Barn, and sixty feet above the dwelling, was capable of proving sufficient water for fire-fighting. When completed at the end of the summer, the family journal commented that the “Hydrants throw water above all the buildings.”

Ludlow Hydrants from Ludlow Valve Company Catalogue, 1878. Souce: http://www.firehydrant.org/pictures/lv01.html

The hydrants, three of which are still in place, were manufactured by the Ludlow Valve Company in Troy, New York. Ludlow Valve was founded by Henry G. Ludlow in Waterford, New York, in 1866 and began making hydrants soon after. Ludlow, an engineer with a degree from Union College, originally a native of Nassau, New York, ran his company into the 1890s. It was the largest producer of fire hydrants in the country. Although the company officially went out of business in 1969, parts for some Ludlow hydrants are still being manufactured.

There is no record of the North Family ever using the hydrants to fight a fire but in the late 1870s the Shakers extended the piping from the hydrant to their new Wash House to power a ten-horsepower water motor manufactured by the Backus Water Motor Company in Newark, New Jersey. The water motor was initially used to power the wash mill and centrifugal extractor for the laundry, but eventually operated the family’s small grist mill, a mechanical wood splitter, and several other smaller machines. In time, the Shakers added lines to the hydrant pipes to provide power to the Sisters’ Workshop for their sewing machines and in 1891 to the Second Dwelling to operate the equipment for the dairy located in its cellar.

Map of North Family Hydrant Locations and Assumed Piping, North Family, Mount Lebanon, NY, as drawn by A. K. Mosley for the Historic American Buildings Survey, 1939.

The use of pressurized hydrants for fire-fighting goes back to the second decade of the nineteenth century but as obviously useful as they were in urban areas, the use of hydrants in rural settings such as the Shaker Village would have been quite unexpected by visitors to Mount Lebanon. The Church and South Families at Mount Lebanon also added hydrants to their arsenal of fire-fighting equipment at about the same time.

First and Second House, North Family, Mount Lebanon, NY, Ca. 1880, James Irving, photographer, Troy, NY, Shaker Museum | Mount Lebanon, 1950.4088.1 This view from the early 1880s shows the hydrant that was meant to protect the Second Dwelling, the Brethren’s Workshop, Forge, and Deacons Workshop. It is the one hydrant that has been removed.

[…] Second Family.” The Shakers had become involved with Brown as they attempted to rebuild following a catastrophic fire in 1875. Brown contracted with the Shakers to use their well-disciplined workforce to manufacture, […]