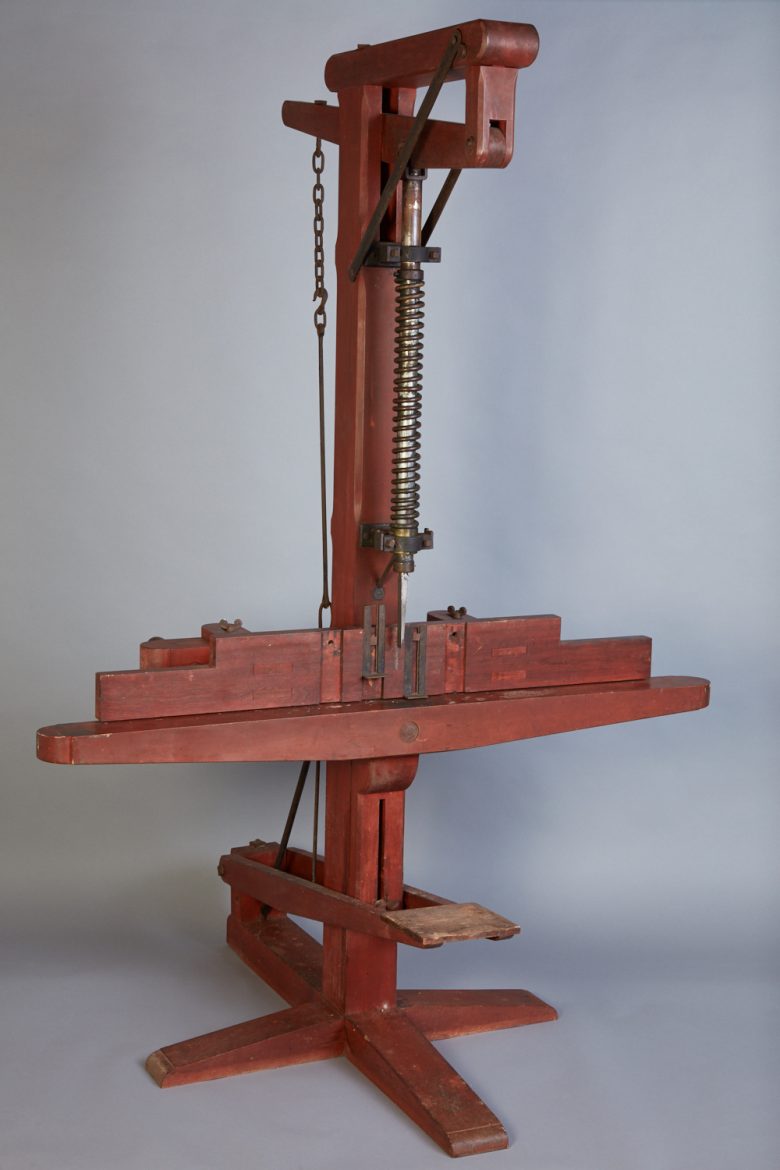

Foot-Operated Mortising Machine (detail of mortising chisel), Church Family, Mount Lebanon, NY, ca. 1842, Shaker Museum | Mount Lebanon: 1961.12843.1. John Mulligan, photographer.

There is a story told about the Shakers that, although probably apocryphal, speaks to the Shakers’ desire to be progressive and advanced in their industrial production. It is said that many a mill and factory owner barred the Shakers from viewing the machinery they used for fear the Shakers would quickly understand how the machinery worked, go […]

There is a story told about the Shakers that, although probably apocryphal, speaks to the Shakers’ desire to be progressive and advanced in their industrial production. It is said that many a mill and factory owner barred the Shakers from viewing the machinery they used for fear the Shakers would quickly understand how the machinery worked, go home, duplicate the machinery, and become competitors in the market.

True or not, the story of a foot-operated mortiser in the collection of Shaker Museum | Mount Lebanon may support the mill and factory owners’ concerns. A mortiser is a tool used to make square or rectangular holes in a piece of wood into which a similarly sized square or rectangular tenon is fit. It does so by pushing a stout chisel into the wood – enlarging and squaring a round pilot-hole. This mortise and tenon joint is very common in the construction of furniture and in building construction. For example, a simple door has at least ten of these joints to hold its vertical and horizontal pieces together. A large Shaker building may have one hundred doors and making all of those mortises by hand, without the aid of machinery, was challenging.

The Church Family at Mount Lebanon was planning to build a new workshop in the summer of 1842. That winter, in anticipation of the number of doors and windows that would have to be mortised, they considered machinery that would make that work less taxing. Brother Orren Haskins, one of the woodworkers in the family, traveled to Pittsfield, Massachusetts, “to see a morticeing [sic] machine with the expectation of making one.” By February that year, he was at work “making a morticeing machine, to mortice doors and window sash for the new shop.”

The foot-operated mortiser in the Museum’s collection has been attributed to Brother Orren both by the description of him as the maker of such a machine and by dating the hardware – the screws and other metalwork – found on the machine. Although it is not known exactly where or who Brother Orren visited in Pittsfield to see a mortiser, new information has been uncovered that suggests what kind of a mortiser he saw on that visit. George Page, a resident of Keene, New Hampshire, patented a mortising machine on March 13, 1833 (Fig. 2). The patent drawing for his mortiser is clearly similar to the mortiser attributed to Brother Orren with the exception that the spring used on Brother Orren’s machine to extract the chisel from the mortise is a spiral spring around the shaft that holds the chisel, whereas on Page’s machine the lifting of the chisel is done by a leaf-spring mounted on the top of the machine. Is this a possible improvement made by the Shaker brother? In 1836, J. A. Fay, also of Keene, New Hampshire, joined Page and several other men in manufacturing the Page’s mortiser. Fay, who went on without his previous partners to found the largest woodworking machinery company in the United States, by January, 1842 had patented an improved mortising machine that made use of a spiral spring rather than the leaf spring used by Page. It is certainly possible that the version of the Page mortiser that Brother Orren saw already had this improvement in place.

There is, to our knowledge, no example of a circa 1842 Page mortiser that has survived so it is hard to know, other than from the patent drawing how closely Brother Orren came to copying the machine, but it appears that Brother Orren was quite good at getting the information he needed to build the machine. The question might be asked as to whether the mortising machine in the Museum’s collection is, in fact, a Page mortising machine. The only answer we have is that there is no record of the Shakers buying a mortising machine at this period and no record of them purchasing the rights to build a patented mortiser.

I appreciate this fine bit of detective work.